DESCRIPTION

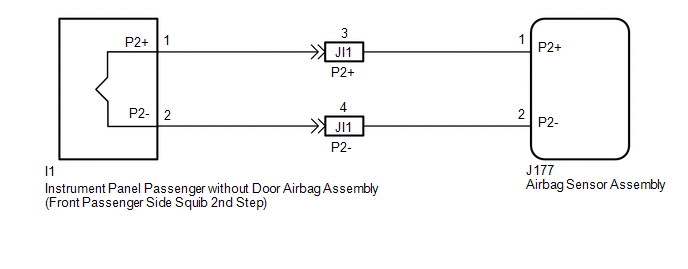

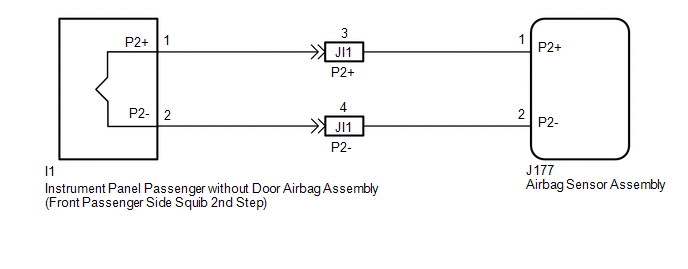

The front passenger side squib 2nd step circuit consists of the airbag sensor

assembly and instrument panel passenger without door airbag.

The circuit instructs the SRS to deploy when deployment conditions are met.

These DTCs are stored when a malfunction is detected in the front passenger side

squib 2nd step circuit.

|

DTC No.

|

Detection Item

|

DTC Detection Condition

|

Trouble Area

|

Warning Indicate

|

Test Mode / Check Mode

|

|

B1815

|

Short in P Squib (Dual Stage - 2nd Step) Circuit

|

One of the following conditions is met:

- The airbag sensor assembly detects a line short circuit signal 5

times in the front passenger side squib 2nd step circuit during the

primary check.

- A instrument panel passenger without door airbag assembly (front

passenger side squib 2nd step) malfunction.

- An airbag sensor assembly malfunction.

|

- Instrument panel wire

- No. 2 instrument panel wire

- Instrument panel passenger without door airbag ssembly (front passenger

side squib 2nd step)

- Airbag sensor assembly

|

Comes on

|

Applicable

|

|

B1816

|

Open in P Squib (Dual Stage - 2nd Step) Circuit

|

One of the following conditions is met:

- The airbag sensor assembly detects an open circuit signal in the

front passenger side squib 2nd step circuit for 2 seconds.

- A instrument panel passenger without door airbag assembly (front

passenger side squib 2nd step) malfunction.

- An airbag sensor assembly malfunction.

|

- Instrument panel wire

- No. 2 instrument panel wire

- Instrument panel passenger without door airbag ssembly (front passenger

side squib 2nd step)

- Airbag sensor assembly

|

Comes on

|

Applicable

|

|

B1817

|

Short in P Squib (Dual Stage - 2nd Step) Circuit (to Ground)

|

One of the following conditions is met:

- The airbag sensor assembly detects a short circuit to ground signal

in the front passenger side squib 2nd step circuit for 0.5 seconds.

- A instrument panel passenger without door airbag assembly (front

passenger side squib 2nd step) malfunction.

- An airbag sensor assembly malfunction.

|

- Instrument panel wire

- No. 2 instrument panel wire

- Instrument panel passenger without door airbag ssembly (front passenger

side squib 2nd step)

- Airbag sensor assembly

|

Comes on

|

Applicable

|

|

B1818

|

Short in P Squib (Dual Stage - 2nd Step) Circuit (to +B)

|

One of the following conditions is met:

- The airbag sensor assembly detects a short circuit to B+ signal

in the front passenger side squib 2nd step circuit for 0.5 seconds.

- A instrument panel passenger without door airbag assembly (front

passenger side squib 2nd step) malfunction.

- An airbag sensor assembly malfunction.

|

- Instrument panel wire

- No. 2 instrument panel wire

- Instrument panel passenger without door airbag ssembly (front passenger

side squib 2nd step)

- Airbag sensor assembly

|

Comes on

|

Applicable

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- After turning the ignition switch off, waiting time may be required before

disconnecting the cable from the negative (-) battery terminal. Therefore, make

sure to read the disconnecting the cable from the negative (-) battery terminal

notices before proceeding with work.

Click here

- When disconnecting the cable from the negative (-) battery terminal while

performing repairs, some systems need to be initialized after the cable is reconnected.

Click here

HINT:

To perform the simulation method, enter check mode (signal check) with the Techstream

(Click here  ), and then wiggle each connector of

the airbag system or drive the vehicle on various types of road (Click here ), and then wiggle each connector of

the airbag system or drive the vehicle on various types of road (Click here

). ).

PROCEDURE

|

(a) Turn the ignition switch off.

|

|

|

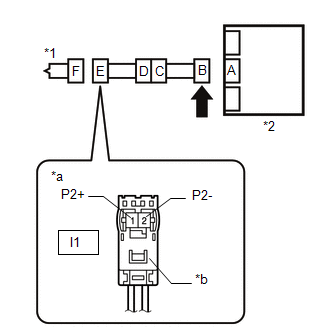

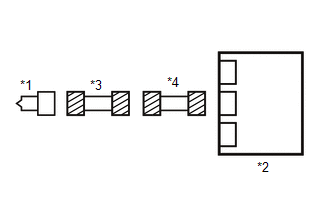

*1

|

Instrument Panel Passenger without Door Airbag Assembly

(Front Passenger Side Squib 2nd Step)

|

|

*2

|

Airbag Sensor Assembly

|

|

*3

|

No. 2 Instrument Panel Wire

|

|

*4

|

Instrument Panel Wire

|

|

|

(b) Disconnect the cable from the negative (-) battery terminal, and wait for

at least 90 seconds.

(c) Check that the connectors are properly connected to the instrument panel

passenger without door airbag assembly (front passenger side squib 2nd step) and

airbag sensor assembly. Also check that the connectors that link the instrument

panel wire and No. 2 instrument panel wire are properly connected.

OK:

The connectors are properly connected.

HINT:

If the connectors are not properly connected, reconnect the connectors and proceed

to the next inspection.

(d) Disconnect the connectors from the instrument panel passenger without door

airbag assembly (front passenger side squib 2nd step) and airbag sensor assembly.

Also disconnect the instrument panel wire from the No. 2 instrument panel wire.

(e) Check that the terminals of the connectors are not deformed or damaged.

OK:

The terminals are not deformed or damaged.

(f) Check that the No. 2 instrument panel wire connector (on the instrument panel

passenger without door airbag assembly [front passenger side squib 2nd step] side)

is not loose, deformed or damaged.

OK:

The connector locking button is not disengaged, and the claw of the lock is not

deformed or damaged.

(g) Check that the short springs of the activation prevention mechanisms of the

instrument panel wire connector and No. 2 instrument panel wire connector are not

deformed or damaged.

OK:

The short springs are not deformed or damaged.

| NG |

|

REPLACE INSTRUMENT PANEL WIRE OR NO. 2 INSTRUMENT PANEL WIRE

|

| OK |

|

|

|

2.

|

CHECK INSTRUMENT PANEL PASSENGER WITHOUT DOOR AIRBAG ASSEMBLY (FRONT

PASSENGER SIDE SQUIB 2ND STEP CIRCUIT)

|

|

(a) Connect the instrument panel wire to the No. 2 instrument panel wire

and airbag sensor assembly.

|

|

|

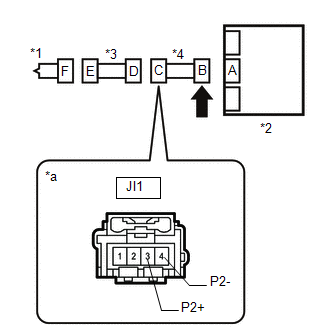

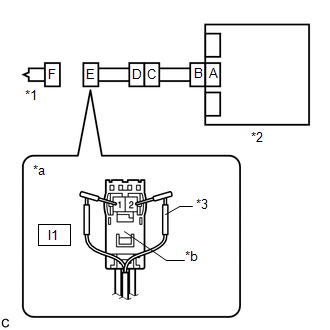

*1

|

Instrument Panel Passenger without Door Airbag Assembly

(Front Passenger Side Squib 2nd Step)

|

|

*2

|

Airbag Sensor Assembly

|

|

*3

|

SST

|

|

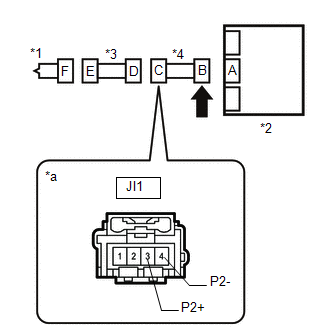

*a

|

Front view of wire harness connector

(to Instrument Panel Passenger without Door Airbag Assembly

[Front Passenger Side Squib 2nd Step])

|

|

*b

|

Color: Black

|

|

|

(b) Connect the white wire side of SST (resistance: 2.1 Ω) to connector E (black

connector).

CAUTION:

Never connect the tester to the instrument panel passenger without door airbag

assembly for measurement, as this may lead to a serious injury due to airbag deployment.

NOTICE:

- Do not forcibly insert SST into the terminals of the connector when connecting

SST.

- Insert SST straight into the terminals of the connector.

SST: 09843-18061

(c) Connect the cable to the negative (-) battery terminal, and wait for at least

2 seconds.

(d) Turn the ignition switch to ON, and wait for at least 60 seconds.

(e) Clear the DTCs.

Click here

(f) Turn the ignition switch off.

(g) Turn the ignition switch to ON, and wait for at least 60 seconds.

(h) Check for DTCs.

Click here

|

Result

|

Proceed to

|

|

DTC B1815, B1816, B1817 or B1818 is not output

|

A

|

|

DTC B1815, B1816, B1817 or B1818 is output

|

B

|

HINT:

Codes other than DTCs B1815, B1816, B1817 and B1818 may be output at this time,

but they are not related to this check.

(i) Turn the ignition switch off.

(j) Disconnect the cable from the negative (-) battery terminal, and wait for

at least 90 seconds.

(k) Disconnect SST from connector E.

| A |

|

REPLACE INSTRUMENT PANEL PASSENGER WITHOUT DOOR AIRBAG ASSEMBLY

|

| B |

|

|

|

3.

|

CHECK FRONT PASSENGER SIDE SQUIB 2ND STEP CIRCUIT

|

(a) Disconnect the instrument panel wire from the airbag sensor assembly.

|

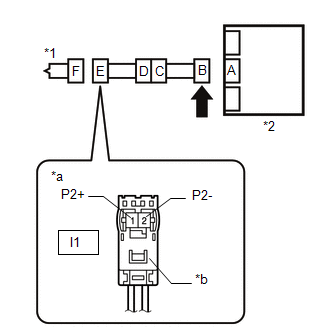

*1

|

Instrument Panel Passenger without Door Airbag Assembly (Front Passenger

Side Squib 2nd Step)

|

|

*2

|

Airbag Sensor Assembly

|

|

*a

|

Front view of wire harness connector

(to Instrument Panel Passenger without Door Airbag Assembly [Front Passenger

Side Squib 2nd Step])

|

|

*b

|

Color: Black

|

|

Release the activation prevention mechanism

|

(b) Check for a short to B+ in the circuit.

(1) Connect the cable to the negative (-) battery terminal, and wait for at least

2 seconds.

(2) Turn the ignition switch to ON.

(3) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection

|

Switch Condition

|

Specified Condition

|

|

I1-1 (P2+) - Body ground

|

Ignition switch ON

|

Below 1 V

|

|

I1-2 (P2-) - Body ground

|

Ignition switch ON

|

Below 1 V

|

(4) Turn the ignition switch off.

(5) Disconnect the cable from the negative (-) battery terminal, and wait for

at least 90 seconds.

(c) Check for an open in the circuit.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

I1-1 (P2+) - I1-2 (P2-)

|

Always

|

Below 1 Ω

|

(d) Check for a short to ground in the circuit.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

I1-1 (P2+) - Body ground

|

Always

|

1 MΩ or higher

|

|

I1-2 (P2-) - Body ground

|

Always

|

1 MΩ or higher

|

(e) Check for a short in the circuit.

(1) Release the activation prevention mechanism built into connector B.

Click here

(2) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

I1-1 (P2+) - I1-2 (P2-)

|

Always

|

1 MΩ or higher

|

(3) Restore the released activation prevention mechanism of connector B to the

original condition.

| NG |

|

GO TO STEP 5

|

| OK |

|

|

|

(a) Connect the connectors to the instrument panel passenger without

door airbag assembly (front passenger side squib 2nd step) and airbag sensor

assembly.

|

|

|

*1

|

Instrument Panel Passenger without Door Airbag Assembly

(Front Passenger Side Squib 2nd Step)

|

|

*2

|

Airbag Sensor Assembly

|

|

|

(b) Connect the cable to the negative (-) battery terminal, and wait for at least

2 seconds.

(c) Turn the ignition switch to ON, and wait for at least 60 seconds.

(d) Clear the DTCs.

Click here

(e) Turn the ignition switch off.

(f) Turn the ignition switch to ON, and wait for at least 60 seconds.

(g) Check for DTCs.

Click here

|

Result

|

Proceed to

|

|

DTC B1815, B1816, B1817 or B1818 is output

|

A

|

|

DTC B1815, B1816, B1817 or B1818 is output

|

B

|

HINT:

Codes other than DTCs B1815, B1816, B1817 and B1818 may be output at this time,

but they are not related to this check.

| A |

|

USE SIMULATION METHOD TO CHECK

|

| B |

|

REPLACE AIRBAG SENSOR ASSEMBLY

|

|

5.

|

CHECK INSTRUMENT PANEL WIRE

|

(a) Disconnect the No. 2 instrument panel wire from the instrument panel wire.

|

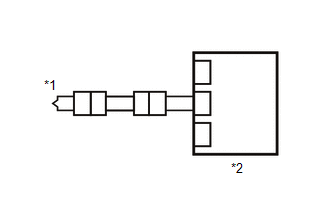

*1

|

Instrument Panel Passenger without Door Airbag Assembly (Front Passenger

Side Squib 2nd Step)

|

|

*2

|

Airbag Sensor Assembly

|

|

*3

|

No. 2 Instrument Panel Wire

|

|

*4

|

Instrument Panel Wire

|

|

*a

|

Front view of wire harness connector

(to No. 2 Instrument Panel Wire)

|

|

Release the activation prevention mechanism

|

(b) Check for a short to B+ in the circuit.

(1) Connect the cable to the negative (-) battery terminal, and wait for at least

2 seconds.

(2) Turn the ignition switch to ON.

(3) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection

|

Switch Condition

|

Specified Condition

|

|

JI1-3 (P2+) - Body ground

|

Ignition switch ON

|

Below 1 V

|

|

JI1-4 (P2-) - Body ground

|

Ignition switch ON

|

Below 1 V

|

(4) Turn the ignition switch off.

(5) Disconnect the cable from the negative (-) battery terminal, and wait for

at least 90 seconds.

(c) Check for an open in the circuit.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

JI1-3 (P2+) - JI1-4 (P2-)

|

Always

|

Below 1 Ω

|

(d) Check for a short to ground in the circuit.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

JI1-3 (P2+) - Body ground

|

Always

|

1 MΩ or higher

|

|

JI1-4 (P2-) - Body ground

|

Always

|

1 MΩ or higher

|

(e) Check for a short in the circuit.

(1) Release the activation prevention mechanism built into connector B.

Click here

(2) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

JI1-3 (P2+) - JI1-4 (P2-)

|

Always

|

1 MΩ or higher

|

(3) Restore the released activation prevention mechanism of connector B to the

original condition.

| OK |

|

REPLACE NO. 2 INSTRUMENT PANEL WIRE

|

| NG |

|

REPLACE INSTRUMENT PANEL WIRE

|

|