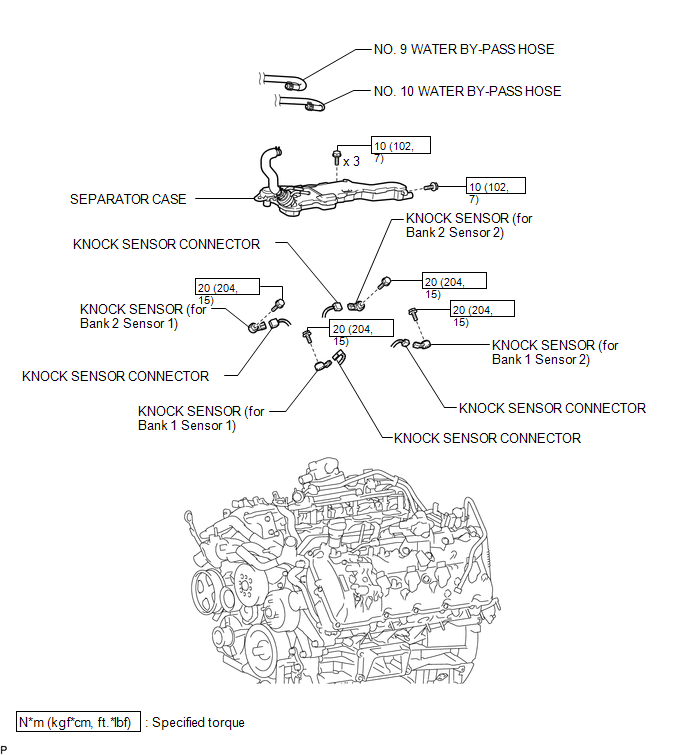

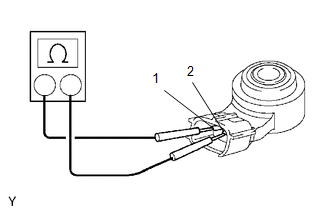

Components COMPONENTS ILLUSTRATION  Inspection INSPECTION PROCEDURE 1. INSPECT KNOCK SENSOR  (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the knock sensor. Installation INSTALLATION CAUTION / NOTICE / HINT HINT: Perform "Inspection After Repairs" after replacing the knock sensor (See page

PROCEDURE 1. INSTALL KNOCK SENSOR HINT: Perform "Inspection After Repairs" after replacing the knock sensor (See page

(b) Connect the 4 knock sensor connectors. 2. INSTALL SEPARATOR CASE (a) Install the separator case with the 4 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} 3. CONNECT NO. 9 WATER BY-PASS HOSE

4. CONNECT NO. 10 WATER BY-PASS HOSE

5. INSTALL INTAKE MANIFOLD (See page Removal REMOVAL PROCEDURE 1. REMOVE INTAKE MANIFOLD (See page 2. DISCONNECT NO. 10 WATER BY-PASS HOSE

3. DISCONNECT NO. 9 WATER BY-PASS HOSE

4. REMOVE SEPARATOR CASE

5. REMOVE KNOCK SENSOR

(b) Remove the 4 bolts and 4 knock sensors. |

Toyota Tundra Service Manual > Rear Axle Shaft: Installation

INSTALLATION PROCEDURE 1. INSTALL REAR AXLE SHAFT OIL SEAL (a) Using SST and a hammer, tap in a new oil seal. SST: 09950-60020 09951-00770 SST: 09950-70010 09951-07150 (b) Apply MP grease to the lip of the oil seal. NOTICE: Do not allow foreign matter, etc. to contact the axle shaft housing hole. 2. ...