DESCRIPTION Refer to P2440 (See page

). ). |

DTC No. | DTC Detection Condition |

Trouble Area | | P2444

P2446 | Secondary air pressure more than 3.0 kPa (23 mmHg) despite ECM commanding air pump to turn off

(2 trip detection logic) |

- Short in air pump circuit

- Open or short in pressure sensor circuit

- Pressure sensor (Air switching valve assembly)

- Air injection control driver (AID)

- ECM

| |

P2445 P2447 | Secondary air pressure less than 1.9 kPa (14 mmHg) despite ECM commanding air pump to turn on

(2 trip detection logic) |

- Air pump assembly

- Open in air pump circuit

- Air injection system piping

- Pressure sensor (Air switching valve assembly)

- Open or short in pressure sensor circuit

- Air injection control driver (AID)

- EGR valve assembly

- Open or short in air pump heater circuit

- Air pump heater relay (AI HTR)

- ECM

| | When secondary air injection is on, the amount of air from the air pump is below the threshold

(2 trip detection logic) | MONITOR DESCRIPTION

The

ECM monitors the pressure in the secondary air passage using the

pressure sensor located on the Air Switching Valve (ASV) of the

Secondary Air Injection (AIR) system. The sensor measures the pressure

in the secondary air passage and transmits a signal to the ECM. If

either of the following conditions occurs, the ECM interprets it as a

malfunction of the AIR system, and illuminates the MIL and stores a DTC:

- The pressure indicated by the pressure sensor does not reach threshold levels despite the ECM turning on the air pump.

- The pressure indicated by the pressure sensor exceeds threshold levels despite the ECM turning off the air pump.

MONITOR STRATEGY |

Related DTCs | P2444: Air pump stuck ON

P2445: Air pump stuck OFF P2446: Air pump stuck ON P2447: Air pump stuck OFF | |

Required Sensors/Components (Main) | Pressure sensor | |

Required Sensors/Components (Related) |

- | | Frequency of Operation |

Once per drive cycle | | Duration |

7 seconds | | MIL Operation |

2 driving cycles | | Sequence of Operation |

None | TYPICAL ENABLING CONDITIONS All |

Monitor runs whenever following DTCs not present |

P0010, P0020 (VVT oil control valve) P0011, P0021 (VVT system - Advance)

P0012, P0022 (VVT system - Retard) P0013, P0023 (Exhaust VVT oil control valve)

P0014, P0024 (Exhaust VVT system - Advance) P0015, P0025 (Exhaust VVT system - Retard)

P0016, P0018 (VVT system - Misalignment) P0017, P0019 (Exhaust VVT system - Misalignment)

P0031, P0032, P0051, P0052, P101D, P103D (Air fuel ratio sensor heater)

P006A, P0107, P0108 (Manifold absolute pressure) P0102, P0103 (Mass air flow meter)

P0112, P0113 (Intake air temperature sensor) P0115, P0117, P0118 (Engine coolant temperature sensor)

P0120, P0121, P0122, P0123, P0220, P0222, P0223, P2135 (Throttle position sensor)

P0125 (Insufficient Coolant Temperature for Closed Loop Fuel Control)

P014C,

P014D, P014E, P014F, P015A, P015B, P015C, P015D, P2195, P2196, P2197,

P2198, P2237, P2238, P2239, P2240, P2241, P2242, P2252, P2253, P2255,

P2256 (Air fuel ratio sensor) P0171, P0172, P0174, P0175 (Fuel system)

P0301 - P0308 (Misfire) P0327, P0328, P032C, P032D, P0332, P0333, P033C, P033D (Knock Sensor)

P0335 (Crankshaft position sensor) P0340, P0342, P0343, P0345, P0347, P0348 (VVT sensor)

P1340 (Camshaft position sensor) P0351 - P0358 (Igniter) P0365, P0367, P0368, P0390, P0392, P0393 (Exhaust VVT sensor)

P0401 (EGR system) P0451, P0452, P0453 (Evaporative Emission System Pressure Sensor)

P0500 (Vehicle speed sensor) P106B (Evap. emission control system Pressure Sensor - Air Injection System Pressure Sensor correlation)

P219A, P219B, P219C, P219D, P219E, P219F, P21A0, P21A1, P21A2, P21A3 (Air-fuel ratio imbalance)

P2431, P2432, P2433, P2436, P2437, P2438 (Secondary Air Injection System Pressure Sensor) | |

Battery voltage | 11 V or more | |

Atmospheric pressure | 45 kPa (338 mmHg) or more | |

Engine | Running | |

AIR monitor during AIR: ON*1 | Completed | |

AIR monitor during AIR: OFF*2 | Completed | |

AIR injection driver fail (open/short or out of range) |

Not detected | | AIR pressure sensor fail (open/short or out of range) |

Not detected | |

*1: AIR monitor during AIR: ON | - | |

Time after AIR in operation | 5 seconds or more | |

AIR pump | ON | | AIR valve |

Open | | Engine speed | 400 to 3750 rpm | |

Intake air amount | Less than 100 gm/s | |

Time after engine start | 1 second or more | |

*2: AIR monitor during AIR: OFF | - | |

Time after AIR in operation | 10 seconds or more | |

AIR pump | OFF | | AIR valve |

Close | | Engine speed | Below 3000 rpm | |

AIR monitor during AIR: ON | Completed | |

Time after engine start | 1 second or more | P2445, P2447 AIR insufficient |

Battery voltage | 11 V or higher | |

Atmospheric pressure | 45 kPa (338 mmHg) or higher | |

Engine | Running | | Air flow pattern check condition during AIR monitor during AIR: ON* |

Completed | | AIR injection driver fail (open/short or out of range) |

Not detected | | AIR pressure sensor fail (open/short or out of range) |

Not detected | | *: Air flow pattern check condition during AIR monitor during AIR: ON |

- | | AIR valve | Open | |

Time after secondary air injection in operation | 1 second or more | TYPICAL MALFUNCTION THRESHOLDS Secondary Air Injection ON (Condition 1) |

Both conditions are met during AIR ON | - | |

Cumulative pressure pulsation | 18 kPa or higher | |

AIR pressure | 1.9 kPa or higher | Secondary Air Injection ON (Condition 2) |

Both conditions are met during AIR ON | - | |

Cumulative pressure pulsation | 18 kPa or higher | |

AIR pressure | Below 1.9 kPa | Secondary Air Injection ON (Condition 3) |

Both conditions are met during AIR ON | - | |

Cumulative pressure pulsation | Below 18 kPa | |

AIR pressure | 1.9 kPa or higher | Secondary Air Injection ON (Condition 4) |

Both conditions are met during AIR ON | - | |

Cumulative pressure pulsation | Below 18 kPa | |

AIR pressure | Below 1.9 kPa | Secondary Air Injection OFF (Condition 1) |

Both conditions are met during AIR OFF | - | |

Cumulative pressure pulsation | 25 kPa or higher | |

AIR pressure | 3 kPa or higher | Secondary Air Injection OFF (Condition 2) |

Both conditions are met during AIR OFF | - | |

Cumulative pressure pulsation | 25 kPa or higher | |

AIR pressure | Below 3 kPa | Secondary Air Injection OFF (Condition 3) |

Both conditions are met during AIR OFF | - | |

Cumulative pressure pulsation | Below 25 kPa | |

AIR pressure | 3 kPa or higher | Secondary Air Injection OFF (Condition 4) |

Both conditions are met during AIR OFF | - | |

Cumulative pressure pulsation | Below 25 kPa | |

AIR pressure | Below 3 kPa | P2444, P2446 AIR pump is stuck ON |

Either condition is met | (a) or (b) | |

(a) AIR OFF Condition 1 | Met | |

(b) AIR OFF Condition 3 | Met | P2445, P2447 AIR pump is stuck OFF |

Either condition is met | (a) or (b) | |

(a) AIR ON Condition 2 | Met | |

(b) AIR ON Condition 4 | Met | P2445, P2447 AIR insufficient |

Either condition is met | (a) or (b) | |

(a) Air flow value at Bank 1 or Bank 2 | 160 L/min. or less | |

(b) Air flow value at Bank 1 and Bank 2 | 160 L/min. or less | MONITOR RESULT

Refer to Checking Monitor Status (See page  ). ). CONFIRMATION DRIVING PATTERN

NOTICE:

- This Secondary Air Injection Check only allows technicians to operate the AIR system for a maximum of 5 seconds.

Furthermore, the check can only be performed up to 4

times per trip. If the test is repeated, intervals of at least 30

seconds are required between checks.

While AIR system operation using the Techstream is prohibited, the Techstream display indicates the prohibition (WAIT or ERROR).

If ERROR is displayed on the Techstream during the test, stop the engine for 10 minutes, and then try again.

- Performing the Secondary Air Injection Check repeatedly may cause damage

to the AIR system. If necessary, leave an interval of several minutes

between System Check operations to prevent the system from overheating.

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch turned to ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

- Start the engine and warm it up.

- Turn the ignition switch off.

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON.

- Turn the Techstream on.

- Clear DTCs (if set) (See page

). ).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the Techstream on.

- Enter the following menus: Powertrain / Engine and ECT / Utility / Secondary Air Injection Check / Automatic Mode.

- Start the engine after the Techstream initialization is finished.

- Perform the System Check operation by pressing ENTER (Next).

- Perform the following to confirm the AIR system pending codes: Press ENTER (Exit).

- Check for pending DTCs.

OK:

No pending DTC is output.

- After the "Secondary air injection check" is completed, check for All

Readiness by entering the following menus: Powertrain / Engine and ECT /

Utility / All Readiness.

- Input the DTC: P2444, P2445, P2446 or P2447.

- Check the DTC judgment result.

|

Tester Display |

Description |

|

NORMAL |

- DTC judgment completed

- System normal

|

|

ABNORMAL |

- DTC judgment completed

- System abnormal

|

|

INCOMPLETE |

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

|

N/A |

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

|

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the test result is INCOMPLETE or N/A and no pending DTC is output,

perform a universal trip and check for permanent DTCs (See page

). ).

HINT:

- If no permanent DTC is output, the system is normal.

- If a permanent DTC is output, the system is malfunctioning.

- Turn the ignition switch off.

WIRING DIAGRAM Refer to DTC P0412 (See page

). ). CAUTION / NOTICE / HINT

HINT:

HINT: Determination by ECM monitoring: The

ECM locates malfunctions in the Secondary Air Injection (AIR) system by

detecting the pressure in the AIR passage between the air pump and Air

Switching Valve (ASV) and stores a DTC. Soon after a cold engine start,

the monitor runs for a short time while the AIR system is both ON and

OFF. The ECM detects both the pressure and the exhaust pulsation and

compares them. The following 8 patterns are AIR system pressure conditions in the AIR system passage. Pressure Condition in Secondary Air Injection System Case 1 |

Air Pump | ON | |

Air Switching Valve | Open | |

Pressure | 1.9 kPa or more | |

Pulsation Detection | Exhaust gas pulsation detected | Pressure Condition in Secondary Air Injection System Case 2 |

Air Pump | OFF | |

Air Switching Valve | Open | |

Pressure | Less than 3.0 kPa | |

Pulsation Detection | Exhaust gas pulsation detected | Pressure Condition in Secondary Air Injection System Case 3 |

Air Pump | ON | |

Air Switching Valve | Closed | |

Pressure | 1.9 kPa or more | |

Pulsation Detection | Exhaust gas pulsation not detected | Pressure Condition in Secondary Air Injection System Case 4 |

Air Pump | OFF | |

Air Switching Valve | Closed | |

Pressure | Less than 3.0 kPa | |

Pulsation Detection | Exhaust gas pulsation not detected | Pressure Condition in Secondary Air Injection System Case 5 |

Air Pump | ON | |

Air Switching Valve | Open | |

Pressure | 1.9 kPa or more | |

Pulsation Detection | Exhaust gas pulsation detected | Pressure Condition in Secondary Air Injection System Case 6 |

Air Pump | OFF | |

Air Switching Valve | Open | |

Pressure | Less than 3.0 kPa | |

Pulsation Detection | Exhaust gas pulsation detected | Pressure Condition in Secondary Air Injection System Case 7 |

Air Pump | ON | |

Air Switching Valve | Closed | |

Pressure | 1.9 kPa or more | |

Pulsation Detection | Exhaust gas pulsation not detected | Pressure Condition in Secondary Air Injection System Case 8 |

Air Pump | OFF | |

Air Switching Valve | Closed | |

Pressure | Less than 3.0 kPa | |

Pulsation Detection | Exhaust gas pulsation not detected |

If

the detected pressure is high, the air pump is assumed to be ON and if

it alternates sharply, the ASV is assumed to be open. The ECM locates

malfunctions from the combination of pressures detected when the AIR

system is ON and OFF. HINT: The

exhaust pulsation value is calculated in the ECM. If the calculated

value exceeds a certain level, the ECM determines that the exhaust

pulsation is in the AIR system.

HINT:

- In case 3 and 7, as the pressure sensor detects a slight pump operation

pulsation, the detected value is not constant. Since the pump outlet is

blocked by closing the ASV, the average pressure is higher than in case 1

(approximately 18 to 25 kPa).

- In case 1, the average pressure is approximately 3 to 11 kPa. The value

of 1.9 kPa indicated in the table above is a threshold for detecting

pump malfunctions.

|

Detected Condition while AIR Operating: Air Pump ON, ASV Open |

Detected Condition while AIR not Operating: Air Pump OFF, ASV Closed |

ECM Determination | DTC Output | |

Case 1 | Case 8 |

Normal | - | |

Case 1 | Case 6 |

ASV stuck open | P2440

or P2442 | |

Case 1 | Case 7 |

Air pump stuck ON | P2444

or P2446 | |

Case 2 | Case 8 |

Air pump stuck OFF | P2445

or P2447 | |

Case 3 | Case 8 |

ASV stuck closed | P2441

or P2443 | |

Case 1 | Case 5 |

ASV stuck open and air pump stuck ON |

P2440 and P2444 or P2442 and P2446 | |

Case 2 | Case 6 |

ASV stuck open and air pump stuck OFF |

P2440 and P2445 or P2442 and P2447 | |

Case 3 | Case 7 |

ASV stuck closed and air pump stuck ON |

P2441 and P2444 or P2443 and P2446 | |

Case 4 | Case 8 |

ASV stuck closed and air pump stuck OFF |

P2441 and P2445 or P2443 and P2447 |

HINT:

- By using the Techstream to perform the Secondary Air Injection Check

operation in the System Check, the air-fuel ratio and the pressure in

the secondary air injection system passage can be checked while the

secondary air injection system is operating. This helps technicians to

troubleshoot the system when it malfunctions. Furthermore, pending codes

also can be checked by performing Utility / Secondary Air Injection

Check / Automatic Mode after the repair.

- Read freeze frame data using the Techstream. Freeze frame data records

the engine condition when malfunctions are detected. When

troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the

air-fuel ratio was lean or rich, and other data from the time the

malfunction occurred.

- System Check:

- The pressure in the secondary air passage can be checked using the Techstream.

- Start the engine and warm it up.

- Turn the ignition switch off.

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON.

- Turn the Techstream on.

- Enter the following menus: Powertrain / Engine and ECT / Utility /

Secondary Air Injection Check / Manual Mode / AIR PUMP 1: ON, ASV1:

OPEN, AIR PUMP 2: ON, ASV2: OPEN and AIR PUMP 1: OFF, ASV1 CLOSE, AIR

PUMP 2: OFF, ASV2 CLOSE.

HINT:

When

Manual Mode is selected, the Techstream initialization (atmospheric

pressure measurement) is performed automatically. The initialization

takes 10 seconds. After the initialization, AIR PUMP and ASV operation

can be selected.

- Start the engine.

- Perform the AIR system forced operation while the engine is idling.

- Check that the air pump (AIR PUMP), ASV and pressure in the AIR system

passage (PRESSURE) displayed on the Techstream indicate the conditions

shown in the table below.

Standard:

|

Tester Operation |

Air Pump |

ASV |

Pressure*1 |

Pulsation*2 |

|

AIR PUMP: ON, ASV: OPEN |

ON |

OPEN |

1.9 kPa or more |

18 kPa or more |

|

AIR PUMP: OFF, ASV: CLOSE |

OFF |

CLOSE |

Less than 3.0 kPa |

Less than 25 kPa |

*1: Average pumping pressure (gauge pressure). The pressure should be 1.9 kPa or more when the AIR system operates.

*2:

The cumulative exhaust pulsation calculated by the ECM. If the

calculated value exceeds a certain level, the ECM determines that the

exhaust pulsation is in the AIR system.

- Turn the ignition switch off.

NOTICE:

- This Secondary Air Injection Check only allows technicians to operate the AIR system for a maximum of 5 seconds.

Furthermore, the check can only be performed up to 4

times per trip. If the test is repeated, intervals of at least 30

seconds are required between checks.

While AIR system operation using the Techstream is prohibited, the Techstream display indicates the prohibition (WAIT or ERROR).

If ERROR is displayed on the Techstream during the test, stop the engine for 10 minutes, and then try again.

- Performing the Secondary Air Injection Check repeatedly may cause damage

to the AIR system. If necessary, leave an interval of several minutes

between System Check operations to prevent the system from overheating.

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch turned to ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

PROCEDURE |

1. | CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2444, P2445, P2446 AND/OR P2447) |

(a) Connect the Techstream to the DLC3. (b) Turn the ignition switch to ON.

(c) Turn the Techstream on. (d) Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

(e) Read DTCs. Result |

Result | Proceed to | |

P2444, P2445, P2446 and/or P2447 is output |

A | | P2444, P2445, P2446 and/or P2447 and P0418 and/or P0419 are output |

B | | P2444, P2445, P2446 and/or P2447 and other DTCs (except P0418 and P0419) are output |

C | If any DTCs other than P0418, P0419, P2444, P2445, P2446 and/or P2447 are output, troubleshoot those DTCs first.

| B |

| GO TO AIR PUMP INSPECTION PROCEDURE |

| C |

| GO TO DTC CHART |

|

A |

| |

| 2. |

PERFORM ACTIVE TEST USING TECHSTREAM (ACTIVATE THE AIR PUMP HEATER) |

| (a) Disconnect the air pump assembly (for bank 1 or bank 2) connector. |

|

(b) Connect the Techstream to the DLC3. (c) Turn the ignition switch to ON and turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the Air Pump Heater.

(e) Measure the voltage according to the value(s) in the table below. Standard Voltage |

Tester Connection | Condition |

Specified Condition | |

D89-1 (APH+) - Body ground |

Activate the Air Pump Heater is ON |

11 to 14 V | |

D90-1 (APH+) - Body ground |

Activate the Air Pump Heater is ON |

11 to 14 V | (f) Reconnect the air pump assembly (for bank 1 or bank 2) connector.

| NG |

| GO TO STEP 4 |

|

OK |

| |

| 3. |

INSPECT AIR PUMP ASSEMBLY (FOR BANK 1 OR BANK 2) (HEATER RESISTANCE) |

(a) Inspect the air pump assembly (for bank 1 or bank 2) (See page

). ).

| NG |  |

REPLACE AIR PUMP ASSEMBLY (FOR BANK 1 OR BANK 2) |

|

OK |

| |

| 4. |

INSPECT AIR PUMP HEATER (AI-HTR) RELAY |

| NG |  |

REPLACE AIR PUMP HEATER (AI-HTR) RELAY |

|

OK |

| |

| 5. |

CHECK AIR PUMP HEATER (AI HTR) RELAY (POWER SOURCE) |

(a) Remove the air pump heater (AI HTR) relay.

| (b) Measure the voltage according to the value(s) in the table below. Standard Voltage |

Tester Connection | Condition |

Specified Condition | |

AI HTR relay terminal 5 - Body ground |

Always | 11 to 14 V | |

|

(c) Reinstall the air pump heater (AI HTR) relay.

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 6. |

CHECK HARNESS AND CONNECTOR (AIR PUMP - AIR PUMP HEATER RELAY, BODY GROUND) |

(a) Remove the air pump heater (AI HTR) relay. (b) Disconnect the air pump assembly (for bank 1 or bank 2) connector.

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance |

Tester Connection | Condition |

Specified Condition | |

AI HTR relay terminal 3 - D89-1 (APH+) |

Always | Below 1 Ω | |

AI HTR relay terminal 3 - D90-1 (APH+) |

Always | Below 1 Ω | |

D89-3 (APHG) - Body ground |

Always | Below 1 Ω | |

D90-3 (APHG) - Body ground |

Always | Below 1 Ω | |

AI HTR relay terminal 3 or D89-1 (APH+) - Body ground |

Always | 10 kΩ or higher | |

AI HTR relay terminal 3 or D90-1 (APH+) - Body ground |

Always | 10 kΩ or higher |

(d) Reinstall the air pump heater relay (AI HTR). (e) Reconnect the air pump assembly (for bank 1 or bank 2) connector.

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 7. |

PERFORM ACTIVE TEST USING TECHSTREAM (SECONDARY AIR INJECTION SYSTEM OPERATION) |

(a) Start the engine and warm it up. (b) Turn the ignition switch off.

(c) Connect the Techstream to the DLC3. (d) Turn the ignition switch to ON.

(e) Turn the Techstream on. (f)

Enter the following menus: Powertrain / Engine and ECT / Utility /

Secondary Air Injection Check / Manual Mode / AIR PUMP 1: ON, ASV1:

OPEN, AIR PUMP 2: ON, ASV2: OPEN and AIR PUMP 1: OFF, ASV1: CLOSE, AIR

PUMP 2: OFF, ASV2: CLOSE. HINT: When

Manual Mode is selected, the Techstream initialization (atmospheric

pressure measurement) is performed automatically. The initialization

takes 10 seconds. After the initialization, AIR PUMP and ASV operation

can be selected. (g) Start the engine. (h) Perform the AIR system intrusive operation while the engine is idling.

(i)

Check that the air pump (AIR PUMP), ASV and pressure in the AIR system

passage (PRESSURE) displayed on the Techstream indicate the conditions

shown in the table below. Standard: |

Tester Operation | AIR PUMP |

ASV | PRESSURE* | |

AIR PUMP: ON, ASV: OPEN |

ON | ON |

1.9 kPa or more | |

AIR PUMP: OFF, ASV: CLOSE |

OFF | OFF |

Less than 3.0 kPa | *: Average pumping pressure. The pressure should be 1.9 kPa or more when the AIR system operates.

(j) Turn the ignition switch off.

NOTICE:

- This Secondary Air Injection Check only allows technicians to operate the AIR system for a maximum of 5 seconds.

Furthermore, the check can only be performed up to 4

times per trip. If the test is repeated, intervals of at least 30

seconds are required between checks.

While AIR system operation using the Techstream is prohibited, the Techstream display indicates the prohibition (WAIT or ERROR).

If ERROR is displayed on the Techstream during the test, stop the engine for 10 minutes, and then try again.

- Performing the Secondary Air Injection Check repeatedly may cause damage

to the AIR system. If necessary, leave an interval of several minutes

between System Check operations to prevent the system from overheating.

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch turned to ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

| NG |

| GO TO STEP 9 |

|

OK |

| |

| 8. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P2444, P2445, P2446 AND/OR P2447) |

(a) Start the engine and warm it up. (b) Turn the ignition switch off.

(c) Connect the Techstream to the DLC3. (d) Turn the ignition switch to ON.

(e) Turn the Techstream on. (f) Clear DTCs (if set) (See page

). ). (g) Enter the following menus: Powertrain / Engine and ECT / Utility / Secondary Air Injection Check / Automatic Mode.

(h) Start the engine after the Techstream initialization is finished. (i) Perform the System Check operation by pressing ENTER (Next).

(j) After operating the AIR system, perform the following to confirm the AIR system pending codes: Press the Exit button.

(k) Check pending DTCs. (l) Turn the ignition switch off.

NOTICE:

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch turned to ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

Result |

Result | Proceed to | |

P2444, P2445, P2446 and/or P2447 is output |

A | | No pending DTC is output |

B |

| B |

| CHECK FOR INTERMITTENT PROBLEMS |

|

A |

| |

| 9. |

CHECK VACUUM HOSE (PRESSURE SENSOR - AIR SWITCHING VALVE) |

(a) Check the vacuum hose connections with the pressure sensor and air switching valve assembly.

(b) Inspect the vacuum hose for blockages and damage. OK: Vacuum hose has no blockages or damage.

| NG |

| REPAIR OR REPLACE VACUUM HOSE |

|

OK |

| |

| 10. |

INSPECT AIR SWITCHING VALVE ASSEMBLY (PRESSURE SENSOR) |

(a) Connect the Techstream to the DLC3. (b) Turn the ignition switch to ON.

(c) Turn the Techstream on. (d)

Enter the following menus: Powertrain / Engine and ECT / Data List /

Air pump pressure (Absolute) and Air Pump2 Pressure (Absolute). (e) Check the pressure displayed on the Techstream.

Standard pressure: 45 to 135 kPa HINT: The Techstream displays the air pump pressure as absolute pressure. Result |

Result | Proceed to | |

OK | A | |

NG (for Bank 1) | B | |

NG (for Bank 2) | C |

| B |

| REPLACE AIR SWITCHING VALVE ASSEMBLY (FOR BANK 1) |

| C |

| REPLACE AIR SWITCHING VALVE ASSEMBLY (FOR BANK 2) |

|

A |

| |

| 11. |

CHECK AIR INJECTION SYSTEM PIPE CONNECTIONS |

(a) Check that all the pipes and hoses between the air pump and ASV are securely connected.

(b) Inspect the pipes and hoses for blockages and damage. OK: AIR system piping has no blockages or damage.

| NG |

| REPAIR OR REPLACE SECONDARY AIR INJECTION SYSTEM PIPING |

|

OK |

| |

| 12. |

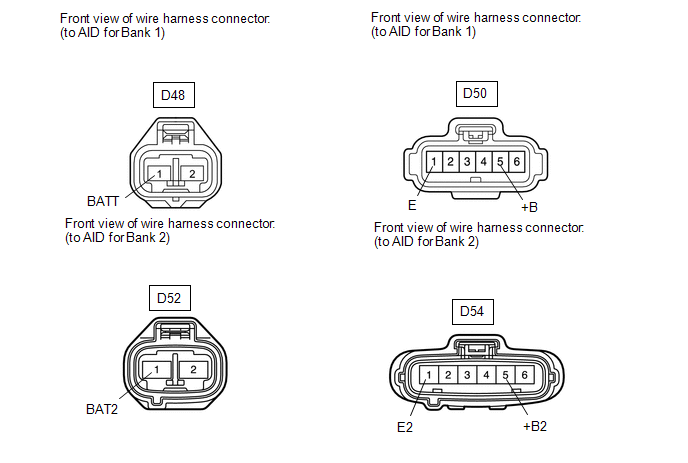

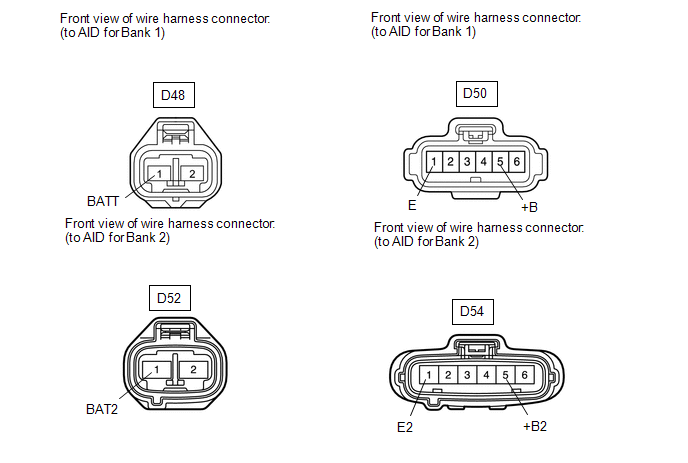

INSPECT AIR INJECTION CONTROL DRIVER (AIR INJECTION CONTROL DRIVER POWER SOURCE CIRCUIT) |

(a) Disconnect the air injection control driver (for bank 1 or bank 2) connectors.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

D50-1 (E) - Body ground |

Always | Below 1 Ω | |

D54-1 (E2) - Body ground |

Always | Below 1 Ω |

(c) Turn the ignition switch to ON. (d) Measure the voltage according to the value(s) in the table below.

Standard Voltage: |

Tester Connection | Switch Condition |

Specified Condition | |

D48-1 (BATT) - Body ground |

Always | 11 to 14 V (near battery voltage) | |

D50-5 (+B) - Body ground |

Ignition switch ON | 11 to 14 V (near battery voltage) | |

D52-1 (BAT2) - Body ground |

Always | 11 to 14 V (near battery voltage) | |

D54-5 (+B2) - Body ground |

Ignition switch ON | 11 to 14 V (near battery voltage) |

| NG |

| REPAIR OR REPLACE AIR INJECTION CONTROL DRIVER POWER SOURCE CIRCUIT |

|

OK |

| |

| 13. |

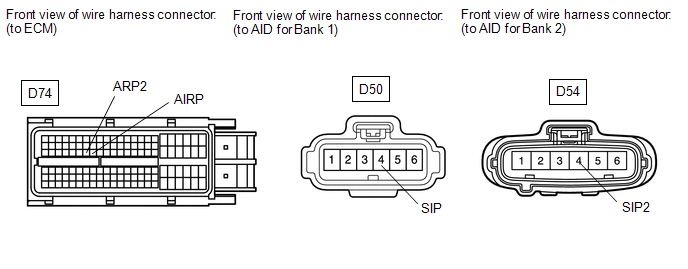

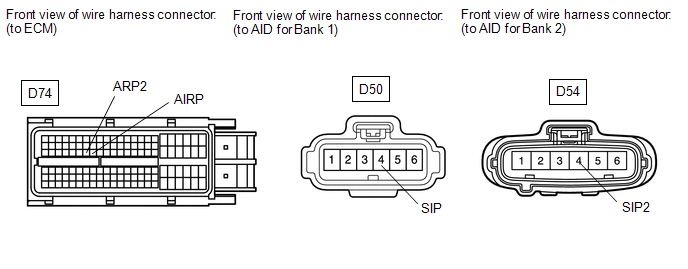

CHECK HARNESS AND CONNECTOR (ECM - AIR INJECTION CONTROL DRIVER) |

(a) Disconnect the ECM connector.

(b) Disconnect the air injection control driver (for bank 1 or bank 2) connectors.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

D74-54 (AIRP) - D50-4 (SIP) |

Always | Below 1 Ω | |

D74-53 (ARP2) - D54-4 (SIP2) |

Always | Below 1 Ω | |

D74-54 (AIRP) or D50-4 (SIP) - Body ground |

Always | 10 kΩ or higher | |

D74-53 (ARP2) or D54-4 (SIP2) - Body ground |

Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 14. |

INSPECT AIR PUMP ASSEMBLY (FOR BANK 1 OR BANK 2) |

| (a) Start the engine and warm it up. | |

(b) Turn the ignition switch off. (c) Connect the 400 A probe of an ammeter to the (+) wire of the air pump.

(d) Connect the Techstream to the DLC3. (e) Turn the ignition switch to ON and turn the Techstream ON.

(f) Start the engine. (g)

Enter the following menus: Powertrain / Engine and ECT / Utility /

Secondary Air Injection Check / Manual Mode / AIR PUMP 1: ON, ASV1:

OPEN, AIR PUMP 2: ON, ASV2: OPEN and AIR PUMP 1: OFF, ASV1: CLOSE, AIR

PUMP 2: OFF, ASV2: CLOSE. HINT: When

Manual Mode is selected, the Techstream initialization (atmospheric

pressure measurement) is performed automatically. The initialization

takes 10 seconds. After the initialization, AIR PUMP and ASV operation

can be selected. (h) Measure the current while the air pump is on and off.

Standard Current: |

Tester Operation | Air Pump |

ASV | Specified Condition | |

AIR PUMP: ON, ASV: OPEN |

ON | OPEN |

10 to 40 A | |

AIR PUMP: OFF, ASV: CLOSE |

OFF | CLOSE |

Below 1 A |

NOTICE:

- This Secondary Air Injection Check only allows technicians to operate the AIR system for a maximum of 5 seconds.

Furthermore, the check can only be performed up to 4

times per trip. If the test is repeated, intervals of at least 30

seconds are required between checks.

While AIR system operation using the Techstream is prohibited, the Techstream display indicates the prohibition (WAIT or ERROR).

If ERROR is displayed on the Techstream during the test, stop the engine for 10 minutes, and then try again.

- Performing the Secondary Air Injection Check repeatedly may cause damage

to the AIR system. If necessary, leave an interval of several minutes

between System Check operations to prevent the system from overheating.

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch turned to ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

| OK |

| GO TO STEP 17 |

|

NG |

| |

| 15. |

REPLACE AIR PUMP ASSEMBLY (FOR BANK 1 OR BANK 2) |

(a) Replace the air pump assembly (for bank 1 or bank 2) (See page

). ).

|

NEXT |

| |

| 16. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P2444, P2445, P2446 AND/OR P2447) |

(a) Start the engine and warm it up. (b) Turn the ignition switch off.

(c) Connect the Techstream to the DLC3. (d) Turn the ignition switch to ON.

(e) Turn the Techstream on. (f) Clear DTCs (if set) (See page

). ). (g) Enter the following menus: Powertrain / Engine and ECT / Utility / Secondary Air Injection Check / Automatic Mode.

(h) Start the engine after the Techstream initialization is finished. (i) Perform the System Check operation by pressing ENTER (Next).

(j) After operating the AIR system, perform the following to confirm the AIR system pending codes: Press the Exit button.

(k) Check pending DTCs. OK: No pending DTC is output. (l) Turn the ignition switch off.

NOTICE:

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch turned to ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

| OK |

| END |

|

NG |

| |

| 17. |

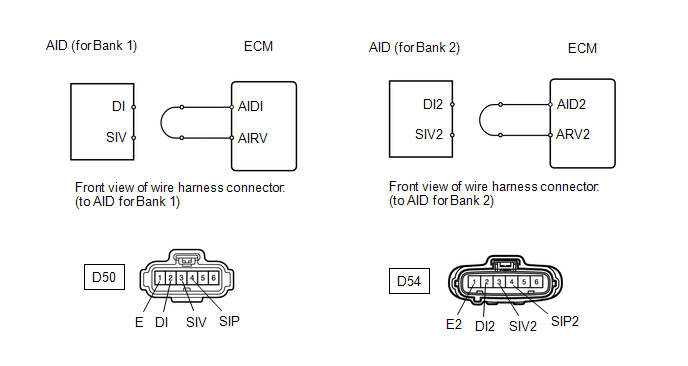

PERFORM ACTIVE TEST USING TECHSTREAM | (a) Disconnect the air injection control driver (for bank 1 or bank 2) connector.

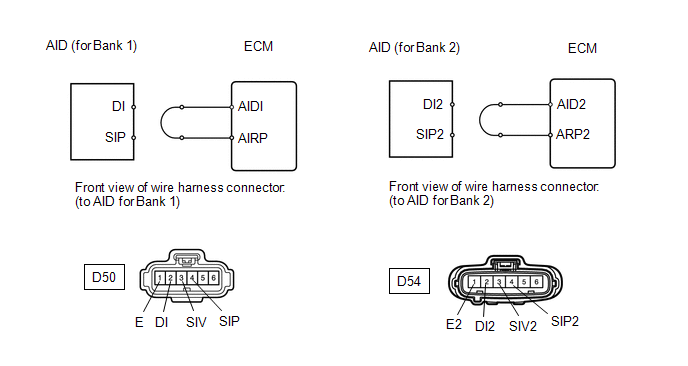

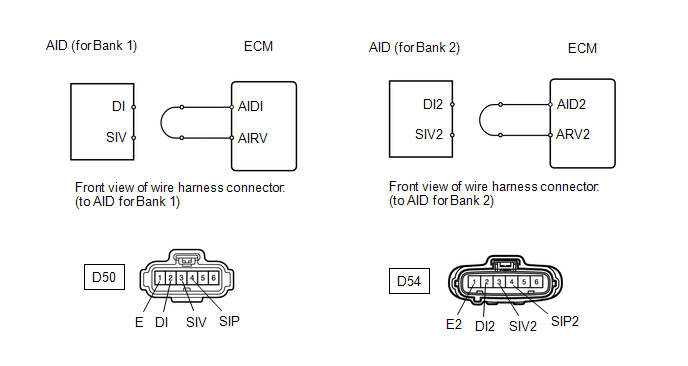

(b) Connect terminals DI and SIV or DI2 and SIV2 of the wire harness connector for the air injection control driver (AID).

(c) Connect the Techstream to the DLC3. (d) Turn the ignition switch to ON and turn the Techstream on.

(e)

Enter the following menus: Powertrain / Engine and ECT / Utility /

Secondary Air Injection Check / Manual Mode / AIR PUMP 1: ON, ASV 1:

OPEN, AIR PUMP 2: ON, ASV 2: OPEN. HINT: When

Manual Mode is selected, the Techstream initialization (atmospheric

pressure measurement) is performed automatically. The initialization

takes 10 seconds. After the initialization, AIR PUMP and ASV operation

can be selected. (f) Start the engine. (g) Perform the AIR system forced operation while the engine is idling.

(h) Measure the voltage between the SIV and E or SIV2 and E2 terminals of the ECM connector when the AIR system is ON and OFF.

(i) Turn the ignition switch off.

NOTICE:

- Performing Secondary Air Injection Check repeatedly may cause damage to

the secondary air injection system. If it is necessary to repeat the

check, leave an interval of several minutes between System Check

operations to prevent the system from overheating.

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | | D50-3 (SIV) - D50-1 (E) |

AIR PUMP: ON, ASV: OPEN | 0.5 to 2 V | |

D54-3 (SIV2) - D54-1 (E2) | AIR PUMP: ON, ASV: OPEN |

0.5 to 2 V | | D50-3 (SIV) - D50-1 (E) |

AIR PUMP: OFF, ASV: CLOSE | 11 to 14 V | |

D54-3 (SIV2) - D54-1 (E2) | AIR PUMP: OFF, ASV: CLOSE |

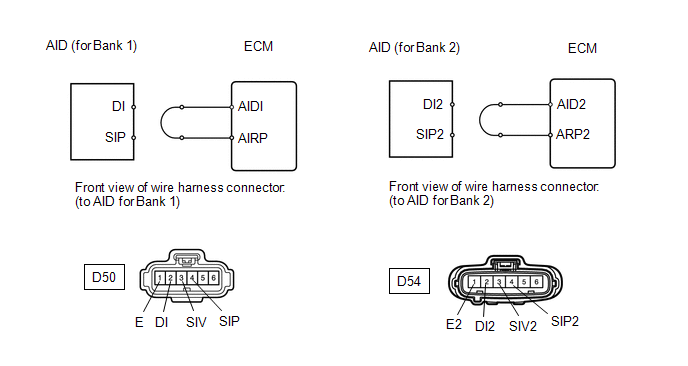

11 to 14 V | (j) Connect terminals DI and SIP or DI2 and SIP2 of the wire harness connector for the air injection control driver.

(k) Connect the Techstream to the DLC3.

(l) Turn the ignition switch to ON and turn the Techstream on. (m)

Enter the following menus: Powertrain / Engine and ECT / Utility /

Secondary Air Injection Check / Manual Mode / AIR PUMP 1: ON, ASV 1:

OPEN, AIR PUMP 2: ON, ASV 2: OPEN. HINT: When

Manual Mode is selected, the Techstream initialization (atmospheric

pressure measurement) is performed automatically. The initialization

takes 10 seconds. After the initialization, AIR PUMP and ASV operation

can be selected. (n) Start the engine. (o) Perform the AIR system forced operation while the engine is idling.

(p) Measure the voltage between the SIP and E or SIP2 and E2 terminals of the ECM connector when the AIR system is ON and OFF.

(q) Turn the ignition switch off.

NOTICE:

- Performing Secondary Air Injection Check repeatedly may cause damage to

the secondary air injection system. If it is necessary to repeat the

check, leave an interval of several minutes between System Check

operations to prevent the system from overheating.

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | | D50-4 (SIP) - D50-1 (E) |

AIR PUMP: ON, ASV: OPEN | 0.5 to 2 V | |

D54-4 (SIP2) - D54-1 (E2) | AIR PUMP: ON, ASV: OPEN |

0.5 to 2 V | | D50-4 (SIP) - D50-1 (E) |

AIR PUMP: OFF, ASV: CLOSE | 11 to 14 V | |

D54-4 (SIP2) - D54-1 (E2) | AIR PUMP: OFF, ASV: CLOSE |

11 to 14 V |

| NG |

| REPLACE ECM |

|

OK |

| |

| 18. |

REPLACE AIR INJECTION CONTROL DRIVER (FOR BANK 1 OR BANK 2) |

(a) Replace the air injection control driver (for bank 1 or bank 2) (See page

). ).

|

NEXT |

| |

| 19. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P2444, P2445, P2446 AND/OR P2447) |

(a) Start the engine and warm it up. (b) Turn the ignition switch off.

(c) Connect the Techstream to the DLC3. (d) Turn the ignition switch to ON.

(e) Turn the Techstream on. (f) Clear DTCs (if set) (See page

). ). (g) Enter the following menus: Powertrain / Engine and ECT / Utility / Secondary Air Injection Check / Automatic Mode.

(h) Start the engine after the Techstream initialization is finished. (i) Perform the System Check operation by pressing ENTER (Next).

(j) After operating the AIR system, perform the following to confirm the AIR system pending codes: Press the Exit button.

(k) Check pending DTCs. OK: No pending DTC is output. (l) Turn the ignition switch off.

NOTICE:

- When performing the Secondary Air Injection Check operation after the

battery cable has been reconnected, wait for 7 minutes with the ignition

switch turned to ON or the engine running.

- Turn the ignition switch off when the Secondary Air Injection Check operation finishes.

| OK |

| END |

|

NG |

| |

| 20. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE EGR STEP POSITION) |

(a) Connect the Techstream to the DLC3. (b) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

HINT:

- When performing the Active Test, make sure the shift lever is in P or N.

- The A/C switch and all accessory switches should be off.

(c) Turn the Techstream on. (d) Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the EGR Step Position.

(e)

Confirm the Throttle Idle Position is ON and check the engine idling

condition and MAP values in the Data List while performing the Active

Test.

HINT:

- Do not leave the EGR valve open for 10 seconds or more during the Active Test.

- Be sure to return the EGR valve to step 0 when the Active Test is completed.

OK: MAP and idling condition change in response to EGR step position as follows.

Standard: |

- | EGR Step Position (Active Test) | |

0 Steps | 0 to 30 Steps | |

Idling condition | Steady idling |

Idling changes from steady to rough idling or engine stall | |

MAP (Data List) |

20 to 40 kPa (150 to 300 mmHg) |

MAP value is at least +10 kPa (75 mmHg) higher than when EGR valve is fully closed |

| OK |

| REPLACE ECM |

|

NG |

| |

| 21. |

INSPECT EGR VALVE ASSEMBLY | (a) Remove the EGR valve assembly (See page

). ). (b) Check if the EGR valve is stuck open.

OK: EGR valve is tightly closed. HINT: Perform "Inspection After Repair" after repairing or replacing the EGR valve assembly (See page

). ).

| OK |  |

REPLACE ECM |

| NG |

| REPLACE EGR VALVE ASSEMBLY | |